The equipment for thermal analysis and calorimetry includes the following instruments: |

DSC 214 Polyma The System Solution for Efficient Characterization of Polymers |

DSC 204 HP Phoenix– High-pressure DSC The high-pressure DSC for specific reactions |

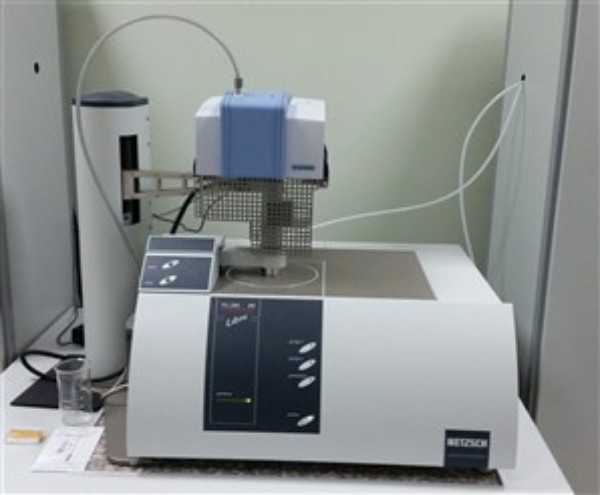

TG 209 F1 Libra The vacuum-tight thermo-microbalance for highest demands |

microDSC7 evo Isothermal calorimeter / high-sensitivity / scanning differential |

Ultra High Pressure Gas Panel up to 1000 bar |

Accelerating Rate Calorimeter 254-(ARC) Testing of Thermal EOR Methods at Reservoir Conditions (high pressure, adiabatic conditions) Using Accelerating Rate Calorimetry (ARC) 1. Experiments at initial pressure till 200 bars (opportunity to fix pressure till 600 bars induced by chemical reactions and heating) 2. Determination of: temperature and time of crude oil self-ignition; rate of self-heating; changes of pressure;kinetic parameters; efficiency of catalysts; maximum rate of reactions 3. Opportunity to inject reagents or gases during the processes at high pressure. |

Isoperibol Calorimeter - Parr 6200 |

Equipment for studying the rheological properties of oil: |

SVM 3000 Stabinger Viscometer Kinematic Viscosity

|

Automatic rheometer MCR-302 |

DSA 5000M+Lovis 3000 |

The equipment for the study of surface properties of oil and oil-containing rocks: |

ASAP 2020 Plus |

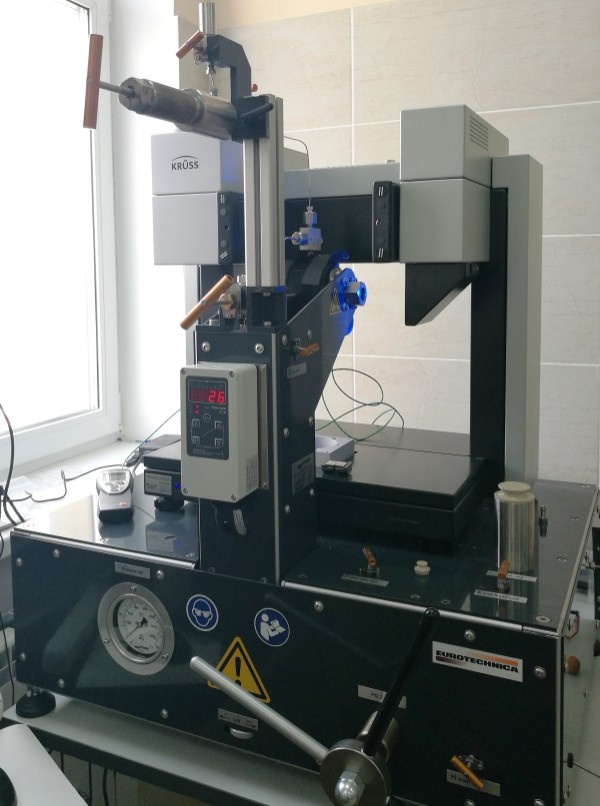

Drop Shape Analyzer – DSA100 Wetting and surface tension under extreme pressures and temperatures |

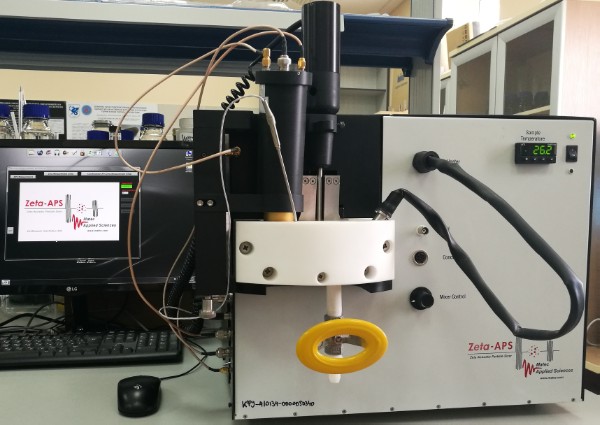

Zeta-APS: Zeta Potential & Particle Sizing Without Dilution |

Equipment for analysis of structure and composition of oil, rocks and catalysts: |

Gas chromatograph Agilent 7890B |

Reactors and pilot plants: |

Parr 4560 Mini Reactors, 100-600 mL |

Ramped Temperature Oxidation Technique for Studies of Crude Oil Experiments at Reservoir Conditions (pressure till 200 bars, temperature till 700 0C) Physical modeling of thermal EOR methods, determination of kinetic parameters, estimation of coal residues, estimation of efficiency of thermal EOR methods on certain boilfield. |

combustion tube Testing of different Thermal EOR: SAGD, CSS, In-situ combustion, HPAI, etc.Pressure till 200 bars Temperature till 700 C |